- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Kev tshawb xyuas ntawm pneumatic conventing kev ua nyob rau hauv kev sib txawv siab gradients

HauvPneumatic Conventing Tshuab, lub siab gradient yog ib qho tseem ceeb tshaj plaws uas piav qhia txog cov dej ntws ntawm cov roj thiab cov khoom hauv cov raj hauv Pipelines. Nws ncaj qha ncaj qha rau kev siv hluav taws xob uas yuav tsum tau ua kom kov yeej kev tawm tsam thaum muaj kev ua tau zoo, ruaj khov, thiab tus nqi-ua hauj lwm zoo. Yog li ntawd, hauv kev tshawb fawb hauv qhov kev ua tau zoo nyob rau hauv kev tsim qauv zoo, txhim kho kev ua haujlwm zoo, thiab tsis muaj peev xwm poob. Kab lus no nthuav tawm ib qho kev sim ntsuas seb puas hloov siab gradient class cuam tshuam pneumatic conveying kev ua.

Cov qauv ntawm pneumamentals ntawm pneumatic conventing & siab gradient

Yuav ua li cas pneumatic conveying ua haujlwm

Pneumatic Conventing TshuabFeem ntau siv cov pa cov khoom siv (piv txwv li, lub tshuab tshuab, compressors) los tsim kom muaj kev kub ceev, propelling cov ntaub ntawv granelines. Raws li cov khoom siv-roj piv thiab ntws nrawm, pneumatic conveying yog categorized ua ob hom loj:

- Dilute-theem conveying: cov khoom siv roj qis-roj, cov roj roj ntau, cov khoom uas raug tshem tawm hauv Airflow. Qhov zoo tagnrho rau luv luv-deb, cov khoom siv tsawg dua.

- Dense-theem conveying: cov khoom siv-roj sib piv, txo cov roj qis, cov khoom txav mus rau hauv plugs lossis txheej. Haum rau kev ncua ntev, muaj peev xwm muaj peev xwm ntau, lossis cov khoom tawg / cov khoom muaj zog.

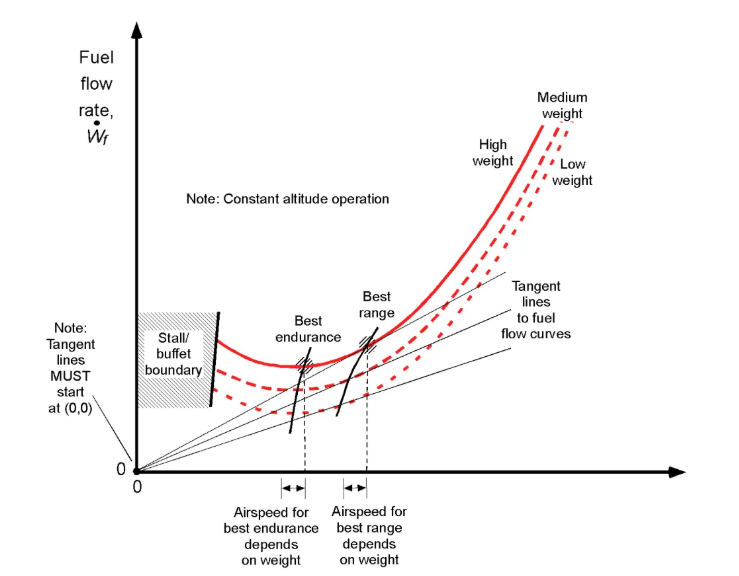

Siab Gradient & nws qhov tseem ceeb

Lub siab gradient (ntsuas hauv PA / M lossis KPA / M) hais txog lub siab hloov ib chav pipeline ntev. Hauv pneumatic conventing, nws qhia tau lub zog poob vim kev sib txhuam, lub ntiajteb txawj nqus, thiab nrawm tiv taus.

Qhov cuam tshuam tseem ceeb ntawm kev ua kom muaj siab gradient:

- Kev Siv Zog: Cov qhab nia siab dua yuav tsum muaj zog ntau los ntawm lub tshuab / compressors.

- Flow Stability: Qhov Zoo Tshaj Plaws Gradients Xyuas kom ntws ruaj khov (piv txwv li, ntom-theem ntsaws txaus). Tsawg heev → daig; Siab heev → ntau dhau hnav & lub zog khib nyiab.

- Kev muaj peev xwm: nyob rau hauv qee qhov ntau, nce cov gradient txhim kho cov ntaub ntawv tawm ntawm.

- Cov Khoom Siv & Pipeline Kev puas tsuaj: Ntau cov gradients nce particle breakage thiab pipeline hnav.

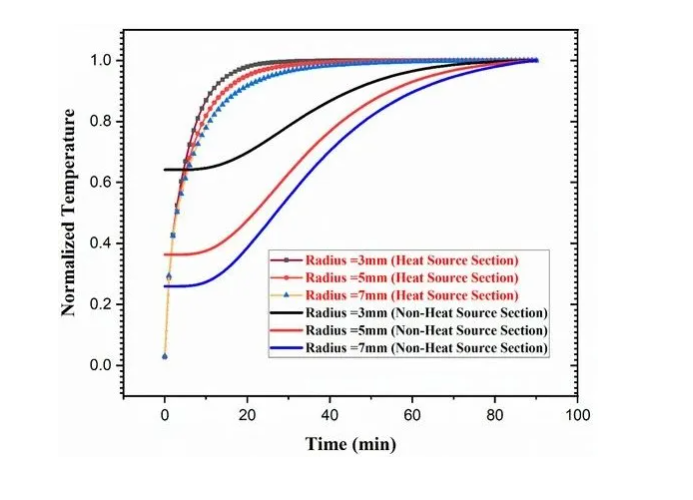

Kev sim ua & kev ntsuas kev ua haujlwm

Kev sim teeb tsa

Ib tus neeg raug pneumatic conveye xeem rig suav nrog:

- CUA TXIAS (BRESSERS, Compressors)

- Pub System Pub Rau (Ntsia Hlau Khoom Siv, Teb Li Li Qub)

- Kev Siv Pipeline (Pob tshab rau Kev Pom Zoo)

- Roj-ruaj khov (cua daj cua dub, lim hnab)

- Qhov hnyav & sau (ntsuas khoom siv los ntawm kev)

- Sensors & Daq System:

- Siab transducers (hauv zos / hauv ntiaj teb gratients)

- Flow metres (roj ntim)

- Kev Ntsuas Ntev (LDV, Piv)

- Kub sensors

Qhov Tseem Ceeb Qhov Ntsuas

- Tag nrho cov siab poob (Δp tag nrho ) = roj-theem (Δ>

- Siab gradient (Δp / l) - core parameter (PA / M)

- Cov khoom loj ntws nrog tus nqi txaus (m s ) - kg / s lossis t / h

- Khoom-roj piv (μ) = m s s g

- Kev Siv Zog (E) = Lub Zog Inget / M S

- Particle Breakage & Pipeline Hnav Cov Nqi

Kev sim sim tseem ceeb

- Siab Grient Vs. CONATEYING PEEV

- Ntau zuj zus Gradient (ntawm ntau dua cov roj nrawm / khoom thauj khoom) boosts) boosts cov khoom siv los ntawm cov khoom siv tawm, tab sis tsis yog-linearly.

- Piv txwv li: rau 2mm yas pellets hauv 100 hli yeeb nkab, raising Δp / l los ntawm 100 mus rau 300 teev mus rau hauv 0.5 txog 2 t / h. Ntxiv ntxiv nce tawm yielded ploj zuj zus rov qab.

- Dilute-theem: tsawg gradients kev pheej hmoo txaus ntshai particle sib luag; Kev kawm tau zoo rau cov neeg nyob ruaj khov.

- Dense-theem: gradients hauv qab 150 teev / m ua rau txhaws; 250-350 PA / m tswj hwm cov ntsaws cov hluav taws xob; > 450 PA / m cuam tshuam rau plugs mus rau hauv cov dilute ntws.

- U-puab nkhaus nkhaus gradient (Δp / l) thiab siv hluav taws xob (e).

- Piv txwv li: txoj kev nrug deb ua tiav kev siv hluav taws xob tsawg (5 kWh / t) ntawm ΔP / L = 50 KPA.

- Cov neeg muaj peev xwm siab (piv txwv li, 400 vs. 200 teev) ob npaug iav bead Breaky (0.5% → 2.5% thiab yeeb nkab hnav.

- Kev hloov pauv siab (nyiag ntsuas) teeb liab qhov tsis muaj peev xwm (piv txwv li, txhaws kev phom sij).

Kev tsim kho txhim kho kom zoo

- Tsim & Xaiv: LAWV LAWV QAUV Ranges rau cov khoom siv (ceev, abraigeness) thiab qhov deb / qhov siab yuav tsum tau ua.

- Kev Ua Haujlwm Ua Si: Hloov cov huab cua / pub tus nqi los tswj Δp / l hauv "cov chaw qab zib" rau kev ua tau zoo.

- Ntse tswj: iot sensors + kabmob tsav tsheb tsav tsheb rau kev ua kom zoo dua qub.

- Hnav txoj kev me me: Siv cov kav dej qab zib ceramic-lined lossis bends bends rau cov khoom muaj abrasive.

- Cov khoom siv uas muaj kev hloov kho tshwj xeeb: ntxiv cov quav nwg lossis hloov cov yeeb nkab roughnise kom hloov gradient kev xav tau.

Xaus Lus & Yav Tom Ntej Outlook

Qhov kev sim sim no qhia tau tias yuav ua li cas lub siab gradients tau ua rau pneumatic kev sib txuas lus zoo, ruaj khov, thiab tus nqi. Kev nce qib yav tom ntej hauv Ai-powered kev twv tswj hwm thiab lub sijhawm rov qab cog lus ntxiv, Tsav Greener, Smarter Industrial conveying daws teeb meem.

Hais Txog Yinchi

Shandong Yinchi Ib puag ncig Kev Tiv Thaiv Kev Tiv Thaiv Co., Ltd.(Yinchi) Tshwj Xeeb hauv AdvancedPneumatic Conventing Tshuabthiab cov khoom siv daws cov kev daws teeb meem. Peb R & D-tsav tsim qauv ua kom muaj zog-siv tau, kev ua tau zoo nyob hauv kev lag luam.

Tiv tauj peb:

📞 + 86-18853147775 | ✉ sdycmachine@gmail.com